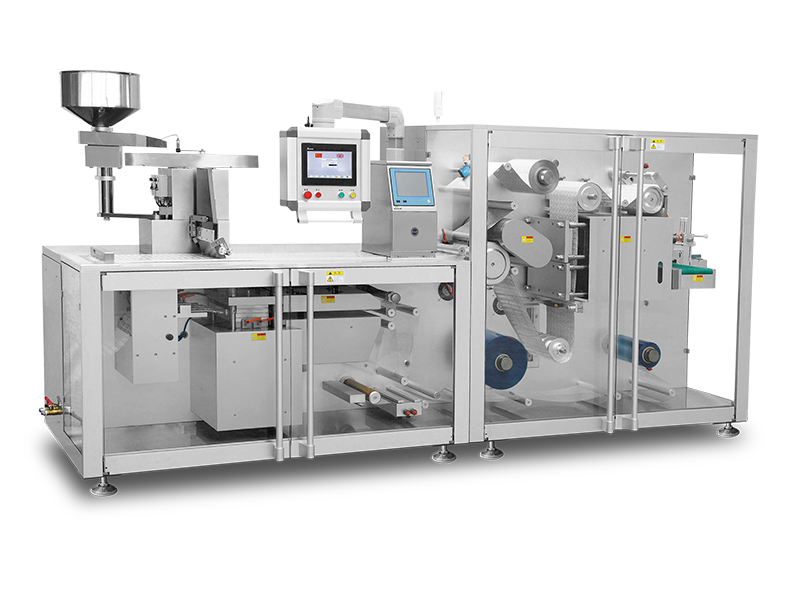

DPT420W+ZHJ300 Ampoule Blister Packing and Cartoning Production Line

DPT420W+ZHJ300 Ampoule Blister Packing and Cartoning Production Line Parameters Model DPT420W-ZHJ300 Tray module Punching speed 10--35 cuts/min Max. forming area 415×240mm Stroke range standard≤60-150mm (customizable≤240mm) Scope of application vials, ampoule, others on request Packaging materials PVC/PVDC Max. width: 420mm thickness:0.15~0.50mm Max. forming depth 25mm (customizable≤45mm) Heating power PVC pre-heating plates: 2x5、Lamination heating:4KW Power supply 380V 50Hz Main motor power 3.0KW Cooling water consumption tap water circular cooling/chiller Noise 40-70dB Cartoner module Carton size(LxWxH) Max:210×108×65mm Min:70×33×17mm Leaflet size(LxW) (100-180)x(100-280)mm Leaflet quality 60-65g/m2 Output 150-300 cartons/min Main motor power 2.2KW Motor frequency 0-50Hz Certificates ISO9001:2000;CE Warranty 1 year Description With easily visible open balcony design and modular concept, DPT420W+ZHJ300 is applicable to tray making and loading for vials, ampoule, injectables (powder), oral liquid or bigger size and special shape of trays for medical appliances, electronics (cells) and cosmetics. Shockproof vase-shaped pockets are suitablefor injectables, ampoule and oral liquids. Driven by servo, it has realized intelligentintegration, high-speed performance. Features Blister module 1.Main drive and main motor installed at the rear of the machine are easy to maintain. Transmission using synchro-belt reduces noise and oil pollution. 2.Workstation adjustment by handwheel equipped with digital position display. 3.Segmental pre-heating with elongated silicone heating plate in heating station results in better forming effect. The upper and lower heating plates can be separated and displaced after machine stop to avoid damaging the plastic nature of the packing material. 4.Traction mechanism independently controlled by servo motor yields stable performance and accurate synchronization. The stroke length can be set directly through the PLC control panel according to the user's blister size. 5.Packing material windingthrough air expansion bearing reel with PVC splicing and joining platform facilitates quicker changeover of packing materials. 6.Force feeding by pick-and-place robot arm ensures accurate placement of blisterswithout damage. Cartoner module 7. Continuous Cartoner ZHJ300 is a high-tech photoelectric, pneumatic and mechanical machine, applicable to a wide range of, blisters, drug bottles, ointments and other similar products. 8. It has fully automatic process of products conveyance and detection, leaflet folding (1-4 times) and transmission, leaflet detection, carton pick-up, erecting and transmission, products into cartons, batch mark embossing, carton sealing (tuck-in or hot melt adhesive). It’s also the right choice for integrated production and mass production. 9. ZHJ300 adopts PLC, photoelectric detection, and HMI. 10. The touch screen has the code and address of each sensor actuator, which can query the consequences caused by the damage of the sensor and the actuator. 11.With overload monitoring system for the whole machine, conveyor chain, and pusher, the machine will stop automatically to minimize the damage and the overloading part will be displayed on the touch screen.